Current Status of the Environmental Impact of Newly Built Business Buildings Using Life Cycle Assessment

ⓒ 2024. KIEAE all rights reserved.

Abstract

Life cycle assessment (LCA) is crucial for achieving carbon neutrality. However, due to the lack of a secured database for buildings that have undergone life cycle assessment, there are no established standards for evaluating the environmental impact of the entire life cycle, including the embodied carbon of buildings. Therefore, this study aims to analyze the current status of the environmental impact throughout the entire process for business facilities that have undergone LCA evaluations.

In this study, we aim to conduct a status analysis on the primary energy consumption and overall environmental impact of business buildings that have undergone LCA among those certified by Green Standards for Energy and Environmental Design (G-SEED). The buildings will be categorized based on G-SEED certification grade, operating entity, structural type, total floor area, and primary energy consumption.

This study conducted a comparison and analysis of LCA evaluation results for newly built business buildings. Building groups were categorized based on building characteristics and primary energy consumption, and the environmental impact assessment results across the life cycle were compared.

Keywords:

Carbon Neutrality, Business Building, Life Cycle Assessment1. Introduction

1.1. Background and Objectives of the Study

Since 1992, when the United Nations Framework Convention on Climate Change was adopted to discuss measures to address climate change, the international community has continuously engaged in discussions on greenhouse gas reduction. Under the 2015 Paris Agreement, a universal system was created in which all countries would participate in greenhouse gas reduction according to their respective circumstances. To this end, carbon neutrality was set as the top agenda item to limit the increase in the Earth's average temperature to within 1.5℃ and create a sustainable planet. The European Union (EU) announced the Fit for 55 package, which aims to reduce greenhouse gas emissions by at least 55% from levels in the 1990s by 2030, with the goal of becoming climate neutral by 2050[1]. Of the 198 countries in the world, 151 countries declared net-zero targets to achieve carbon neutrality[2]. South Korea and the United States announced the target of carbon neutrality by 2050 and China by 2060 as their respective goals for the 2030 Nationally Determined Contributions (NDC)[3].

Carbon neutrality means achieving net emissions of zero to prevent any further increase in greenhouse gas concentrations in the atmosphere, and the scope of carbon neutrality1) is also expanding from Scope 1 and 2 to Scope 3[4]. Accordingly, reducing greenhouse gases in buildings extends beyond the operation stage to include greenhouse gases emitted throughout the entire life cycle, such as from material extraction and processing to building construction, maintenance, renovation, and dismantling or demolition and disposal, making the life cycle assessment (LCA) increasingly important.

To create environmentally friendly buildings, many countries around the world are implementing green building certification systems, and an increasing number of countries are adopting the LCA as a certification criterion. In the United States, the Leadership in Energy and Environmental Design (LEED) certification program requires an LCA to be conducted for the Building Life-Cycle Impact Reduction credit of the Materials and Resources category, and evaluation scores are assigned based on the rate of environmental impact reduction compared to the standard building[5]. The UK's Building Research Establishment Environmental Assessment Method (BREEAM) was the first certification system to introduce LCA for buildings as evaluated in the “Mat.1 Environmental impacts from construction products - Building life cycle assessment (LCA)” portion of the Materials category. It assesses carbon emissions not only during operation stage but from the design stage as well by comparing them with benchmark buildings[6]. South Korea's Green Standards for Energy and Environmental Design (G-SEED) has applied the LCA of buildings as part of innovative design expertise since 2016, and additional points can be earned when an LCA report is submitted for a certified building[7].

Research on the LCA of buildings in South Korea began in the early 2000s. Kanghee Lee et al. conducted an environmental impact study based to the structural forms of residential-commercial buildings[8]. At the time, it was difficult to acquire a database on domestic materials, so the authors utilized an interindustry relation table issued by the Bank of Korea to estimate material application by connecting it to economic activities in the construction sector, conducting an LCA based on interindustry analysis. Cho Kyunhyeong et al. analyzed the environmental impact of each type of building envelope at each stage[9]. Taehoon Hong et al. used LCA techniques to analyze the environmental impact reduction effects of certified eco-friendly buildings. They found that the environmental impact of certified buildings was greater, showing that G-SEED certification does not guarantee a reduction in environmental impact[10]. Go Myeongjin et al. built a Life Cycle Inventory (LCI) database for major input materials for residential-commercial buildings, providing data for performing LCAs[11]. Choi Dooseong et al. conducted an LCA for school facilities, analyzing processes with a high environmental impact[12]. Various studies on domestic LCA have analyzed building systems, structures, materials, and processes. However, most studies were conducted on specific data and specific buildings, and there are few papers presenting the level of environmental impact of new buildings based on LCA.

The standards related to energy consumption in newly constructed buildings specify energy consumption during the operation stage (heating, cooling, hot water, lighting, and ventilation) in the certification of the building’s energy efficiency grade. However, there are no established standards for assessing environmental impact from a whole-life-cycle perspective. While LCA is essential for achieving carbon neutrality, the lack of a results database for buildings that have undergone LCA means that there are no standards for assessing the environmental impact of the entire life cycle, including the embodied carbon of buildings. Against this backdrop, this study aims to conduct an analysis of the current state of the environmental impact of the life cycle for business buildings that have undergone LCAs.

1.2. Methods and Scope of the Study

To review the trend of LCAs through an analysis of the current state of G-SEED LCAs and to explore directions for future improvement, this study conducted an analysis of the state of primary energy consumption and the LCA of business buildings that have undergone the assessment from among buildings that have received G-SEED certification. Building groups were categorized based on their G-SEED certification grade, operating entity, structural type, total floor area, and primary energy consumption, and a comparative analysis was performed for primary energy consumption and the life-cycle environmental impact for each building group. The life-cycle environmental impact was analyzed with a focus on greenhouse gas emissions, divided into the stages of production, construction, operation, and disposal.

2. Research Methods

2.1. Overview of the Life Cycle Assessment

The LCA is an environmental impact assessment method that quantifies the amount of energy and materials used and emitted throughout all processes of a product or service—from raw material processing, manufacturing, transportation, use, and disposal—to comprehensively evaluate the potential impact on the environment with the aim of improving and reducing this impact[13]. LCAs of buildings include the production of construction materials, transportation to the site and construction, the use and maintenance of the building, and the demolition and disposal of the building. The input of materials and energy used at each stage are assessed.

The LCA was first introduced to G-SEED in 2016. Six LCAs were conducted in 2017, and by 2022, a total of 426 buildings had obtained LCA scores (Table 1.), with the number of buildings obtaining LCAs for both main certification and preliminary certification increasing each year. In 2022, 18.4% of the total 2,313 certifications conducted LCAs, of which 97, or 22.8%, were business buildings.

The method of conducting LCAs was evaluated according to the LCA standards of G-SEED 2016. Depending on the scope of the LCA, this was divided into Full LCA and Streamlined LCA, and the buildings analyzed in this study were all buildings that had undergone Full LCA. In accordance with G-SEED standards, the LCA of all buildings underwent third-party verification. The statement for building materials was based on the quantity in the as-built drawing and completion statements, and the completion statement was for materials confirmed through a confirmation letter from the responsible supervisor. A 99% cut-off was applied for materials input during the production process. The life-cycle stages can be subdivided depending on the evaluator, but the LCA reports analyzed in this study divided the evaluation scope into four stages: production, construction, operation, and disposal. The lifespan of the building was assumed to be 50 years, and materials used for maintenance during the operation stage were included. Energy consumption at the operation stage was calculated based on the energy simulation results used for the building’s energy efficiency grade. The environmental impact category must include the global warming potential (greenhouse gas emissions) and at least two of the six major environmental impact categories, including resource consumption, global warming, impact on the ozone layer, acidification, eutrophication, and photochemical oxidant production. In this study, the values for greenhouse gas emissions among the six major environmental impact categories were compared.

2.2. Overview of the Surveyed Buildings

This study analyzed buildings that received main certifications from among the 97 newly built business buildings that submitted LCA results in 2022, and the analysis was conducted on 30 sites, with three sites excluded due to unusual features. Multipurpose buildings that combine business buildings with buildings for other purposes were excluded from the analysis. An overview of the surveyed buildings is provided in Table 2.

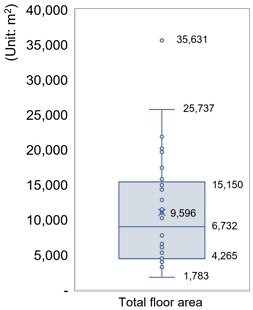

The certification grades of the surveyed buildings included 24 Excellent (Green 2), two Good (Green 3), and four Certified (Green 4). The geographical distribution of buildings was spread across the country, including the Central Region, Southern Region, and Jeju Island. Among them, Seoul had the highest count with 13 buildings, followed by Gyeonggi, Incheon, and Busan. Classifying this based on the coefficient of the heat transmission of the buildings by region, there were two in Central Region 1, 22 in Central Region 2, five in the Southern Region, and one on Jeju Island. The operating entities of the buildings were divided into public and private. The structural materials of buildings, which account for a high proportion in the LCA of materials, were broadly categorized as RC and SRC[14]. The size of the surveyed buildings ranged from small with a total floor area of 1,783m2 to large with a total floor area of 35,631m2, and the sizes of the buildings were classified based on the standard of 10,000 m2. The distribution of total floor area of the surveyed building is shown in Fig. 1.

Energy consumption during the operation stage was determined using the building's energy efficiency grade. The distribution of energy efficiency grades for the surveyed buildings included four with a grade of 1+++, 21 with a grade of 1++, three with a grade of 1+, and two with a grade of 1. The standards for energy consumption were divided into Certified Zero-Energy Buildings (Certified ZEBs); Low-Energy Buildings that have not received ZEB certification but meet the standard of a source energy use intensity of 140kWh/m2, which is a standard for certification; and New Buildings that do not meet the Certified ZEB standards. The results showed that there were six Certified ZEBs, 19 Low-Energy Buildings, and five New Buildings.

3. Results of Building Analysis

3.1. Primary Energy Consumption

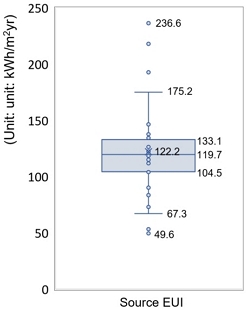

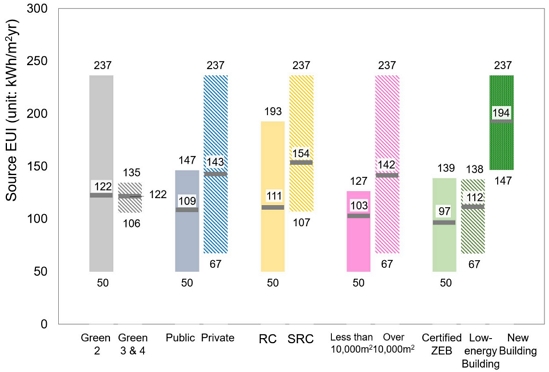

Because energy consumption during the operation stage constitutes the highest proportion in the results of the LCA, a comparison of primary energy consumption based on building characteristics was conducted (Table 3.). The average primary energy consumption for all buildings was 122.2 kWh/m2yr, with a distribution ranging from a minimum of 49.6 to a maximum of 236.6 kWh/m2yr (Fig. 2.).

The results as categorized according to G-SEED certification grades show that the average primary energy consumption was similar. However, when examining the distribution range, Green 2 had a wide distribution, ranging from 236.6 to 49.6 kWh/m2yr. In contrast, Green 3 and 4 had a very narrow distribution, but there are limitations to generalizing due to the small number of buildings analyzed for Green 3 and 4.

Classification based on the building’s operating entity reveals that public buildings had lower energy consumption compared to private buildings. This can be attributed to the regulations on the rationalization of energy use by public institutions, according to which buildings larger than 1,000m2 are required to obtain ZEB certification and it is mandatory to install new and renewable energy facilities and high-efficiency energy equipment, resulting in lower primary energy consumption than in private buildings. All public buildings were over 1,000m2, but the buildings surveyed in this study received main certifications in 2022, so their approval for usage was granted in 2022. As the mandatory regulations for ZEB certification entered into effect in 2022, the obligation for ZEB certification did not apply to these buildings.

Classification based on the building’s structural type indicates that the primary energy consumption of buildings with RC structures was lower than those with SRC structures. Rather than the building’s structure being a cause of the difference in energy consumption, it appears that the difference in primary energy consumption was because out of the eight sampled buildings with SRC structures, all were rated with a low energy efficiency rating of Grade 1.

Regarding the size of the buildings, those with an area exceeding 10,000m2 showed higher primary energy consumption compared to those under 10,000m2, and the range between the minimum and maximum values also appeared to be wider. According to a study by Suyeon Ha, actual energy consumption increases as the total floor area increases due to the greater use of heating, cooling, lighting, and ventilation EUI. This phenomenon is attributed to the difficulties in individual control and higher lighting density in business buildings with larger floor areas[15]. Though there may not be differences in lighting density in new buildings based on the building's size, it is believed that primary energy consumption increases as the total floor area increases due to the increased capacity of facility systems such as heating and cooling facilities and ventilation systems.

When categorizing by primary energy consumption, Certified ZEBs and Low-Energy Buildings exhibited a similar distribution. Certified ZEBs showed an average primary energy consumption of 96.7 kWh/m2yr, indicating lower consumption than the average of 111.5 kWh/m2yr for Low-Energy Buildings. This suggests that the installation of new and renewable energy systems to increase energy self-sufficiency resulted in reduced primary energy consumption during the operation stage.

3.2. Life-Cycle Environmental Impact

The life-cycle environmental impact assessment results were categorized based on the building's characteristics and primary energy consumption. This is because the building's characteristics are closely related to its operation and planning elements, while primary energy consumption significantly influences energy consumption during the operation stage. The life cycle was classified into production, construction, operation, and disposal, and the minimum, average, and maximum values for each stage were compared. Here, the life cycle represents the minimum, average, and maximum of the life cycle for each building rather than the sum of the minimum or maximum values.

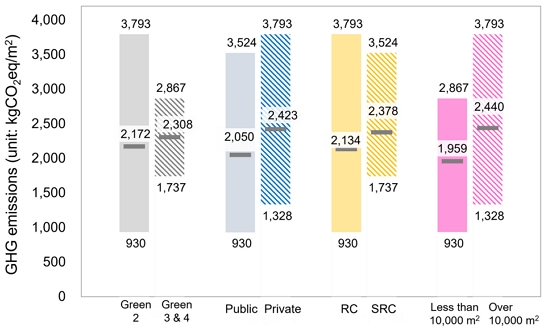

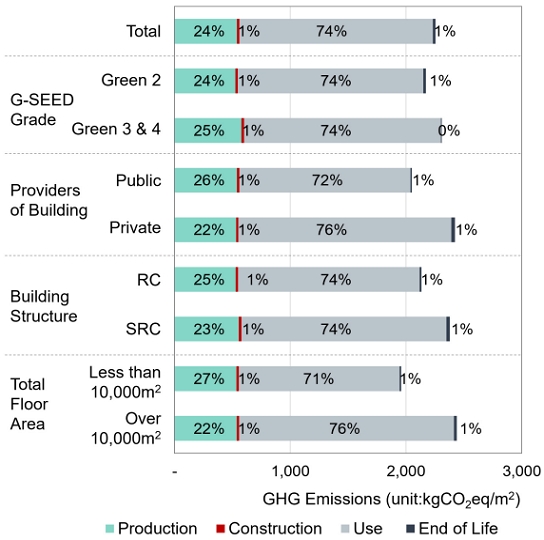

The life-cycle environmental impact assessment for business buildings ranged from 929.7 to 3,897.3 kgCO2eq/m2, with an average of 2,254.1 kgCO2eq/m2. This falls within a range similar to that of the evaluation results per unit area in previous studies[16,17]. Table 4. and Fig. 4. present the results of the life-cycle environmental impact assessment based on G-SEED certification grades, operational entities, building structures, and total floor area. In terms of environmental impact, the use and production stages accounted for 74% and 24%, respectively, while the construction and disposal stages were similar at 1% each (Fig. 5.). Similar to the results for primary energy consumption, the average environmental impact of G-SEED certification Grade 2 and Grades 3 and 4 were similar. However, the number of surveyed buildings was too small to distinguish differences according to building characteristics. In other words, there appeared to be no difference in environmental impact assessment based on G-SEED certification grades. This suggests that, as the evaluation criterion in G-SEED is innovative design expertise, points are not assigned based on the evaluation results but on the basis of whether an LCA took place. As a result, there seems to be no active reduction effect in terms of environmental impact.

The most significant difference in the classification based on the operating entity was observed in the use stage. Since the primary energy consumption of public buildings is low, its environmental impact during the use stage was also calculated to be low. The use stage accounted for 72% of the entire life cycle, a decrease compared to 76% for private buildings. However, there was no significant difference between the production and construction stages based on the operating entity.

In terms of the characteristics of building structures, the environmental impact during the production and construction stages was higher for SRC structures compared to RC structures. The primary building materials for SRC structures include ready-mixed concrete, rebar, and section steel, while those for RC structures consist of ready-mixed concrete and rebar. Embodied carbon emissions vary based on the amount of each material used. According to Kim et al., replacing columns from RC structures to SRC structures results in lower embodied carbon emissions[18]. However, according to a study by Kanghee Lee et al., a comparison of environmental impacts according to the structural type of residential-commercial buildings showed that energy consumption during construction is higher for SRC structures than for RC structures, but the embodied carbon and sulfur compound emissions from materials are lower for SRC structures[8]. The differences between RC and SRC structures appear to be less significant than those among other building characteristics. The quantity of materials used in the building appears to be more important than the structural form.

The results based on classification by total floor area showed no significant differences based on the size of the building in the production and construction stages. However, differences emerged during the use stage. For buildings larger than 10,000m2, the use stage accounted for 76% of their total environmental impact. This indicates that the environmental impact of larger buildings is higher due to increased energy consumption during the use stage. In terms of building characteristics, the size of the total floor area seems to be the most distinctive feature.

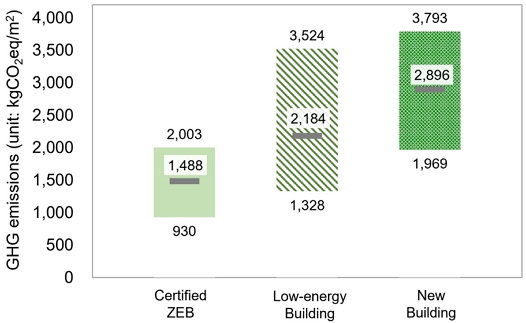

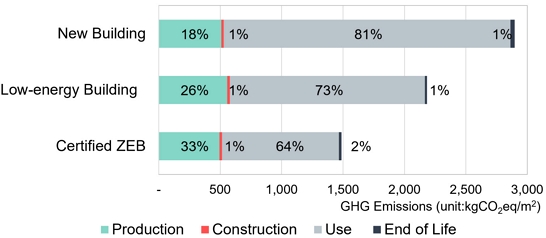

The results of the environmental impact analysis based on primary energy consumption are as follows: the average environmental impact results for Certified ZEBs, Low-Energy Buildings, and New Buildings were 1,488.0, 2,184.2, and 2,897.7 kgCO2eq/m2, respectively (Table 5.). Fig. 6. illustrates the life-cycle environmental impact results, and there is a clear difference based on primary energy consumption.

The emissions during each life cycle stage indicated that Low-Energy Buildings exhibited the highest emissions during the production stage, while Certified ZEBs and New Buildings showed similar results. Emissions during the construction stage were similar for all three building types. The most significant difference occurred during the operation stage. The operation stage was assumed to be 50 years and includes annual energy consumption and replacement costs, and it appears to be greatly affected by the building’s primary energy consumption. In contrast to the emissions during the operation stage for Certified ZEBs, which ranged from 446.9 to 1,390.0 kgCO2eq/m2, the operation stage emissions for newly built buildings were very high, ranging from 1,444.1 to 3,181.0 kgCO2eq/m2. Similar to the production and construction stages, there appears to be no significant differences in the disposal stage in terms of the classification of building groups.

When analyzing the proportions of greenhouse gas emissions for each stage as shown in Fig. 7., the proportion for the operation stage decreased from 81% for new buildings to 64% for certified buildings. This reduction is attributed to the increased input of building materials to reduce the building’s energy consumption. Previous studies evaluating low-energy or net-zero energy buildings have shown similar trends, in which reduced emissions during the operation stage led to the proportion of embodied carbon or embodied energy increasing[19-21]. Utilizing new and renewable energy to achieve net-zero energy reduces energy consumption during the operation stage, making the emissions during the production, construction, and disposal stages more critical. Therefore, to achieve carbon-neutral buildings, effort is needed to reduce the quantity of input materials through design optimization and to decrease embodied carbon emissions by developing materials with reduced greenhouse gas emissions.

4. Conclusion

This study investigated the current status of building environmental impact assessments by categorizing the LCA results of newly built business buildings into primary energy consumption and life-cycle environmental impact assessment and analyzing them according to the characteristics of the buildings.

- (1) No meaningful findings were derived regarding the environmental impact based on G-SEED certification grades due to the limited number of surveyed subjects. It appears that no active reduction in environmental impact has been carried out because the current evaluation criterion is innovative design expertise, and there are no standards for reduction grades. In the future, standards for grades will need to be established to encourage the proactive reduction of environmental impact.

- (2) Differences in primary energy consumption and environmental impact were observed based on the building's operational entity and total floor area. Public buildings exhibited lower environmental impact assessment results, as legal regulations subject them to high standards in terms of energy consumption. Compared to small and medium-sized buildings, large buildings showed higher energy consumption and, as a result, higher environmental impact emissions during the use phase due to installed capacity and building use.

- (3) Classification of building groups based on primary energy consumption revealed that Certified ZEBs had low energy consumption during the operation phase, leading to reduced environmental impact emissions during the use stage. With the strengthening of obligations for zero-energy certification, the proportion of embodied energy will increase in the future, making building design and use of low-carbon materials more important.

To establish standards for achieving carbon neutrality in the future, further analysis of life-cycle environmental impact assessment results with an expanded sample size covering diverse building groups is needed. This can serve as a foundation for establishing standards for life-cycle environmental impact, including embodied carbon. The findings of this study are expected to be utilized as foundational data for the development of standards for future life-cycle environmental impact assessments.

Acknowledgments

This study was conducted with support from the National Research Foundation of Korea with funding from the government (Ministry of Science and ICT) in 2023 (No. RS-2023-00217322).

Notes

References

- European Council, European climate law: Council and parliament reach provisional agreement, https://www.consilium.europa.eu/en/press/press-releases/2021/05/05/european-climate-law-council-and-parliament-reach-provisional-agreement/, , 2023.12.05.

- Energy & Climate Intelligence Unit, Net Zero Tracker: Net Zero Emissions Race, https://eciu.net/netzerotracker, , 2023.12.01.

- Climate Action Tracker, Official website, https://climateactiontracker.org/, , 2023.12.01.

- Building Innovation Hub, Understanding building emissions, https://buildinginnovationhub.org/resource/get-started/understanding-building-emissions/, , 2023.12.05.

- USGBC, LEED v4.1 for building design and construction, U.S. Green Building Council, 2023.

- BRE, BREEAM UK New Construction version 6.1 Technical Manual, 2023.06.28. https://bregroup.com/products/breeam/breeam-technical-standards/breeam-new-construction/, 2023.06.28.

-

한국건설기술연구원, 녹색건축 인증기준 해설서-신축 비주거용 건축물, 2023.07.

Korea Institute of Civil Engineering and Building Technology, G-SEED certification standards guidelines-New non-residential buildings, 2023.07. -

이강희, 김상범, 양재혁, 주상복합건물의 구조형식에 따른 환경영향 비교연구, 대한건축학회논문집 계획계, 제20권 제7호, 2004.07, pp.47-54.

K.H. Lee, S.R. Kim, J.H. Yang, A study on the comparison of the building environment impacts according to structural type in the residential complex building, Journal of the Architectural Institute of Korea Planning & Design, 20(7), 2004.07, pp.47-54. -

조균형, 김용식, 박병윤, LCA 방법을 이용한 건물 외피시스템의 환경영향 평가, 한국생활환경학회지, 제12권 제2호, 2005.06, pp.140-147.

K.H. Cho, Y.S. Kim, B.Y. Park, Evaluation of the environmental load of external wall system by using the full scale life cycle assessment, Journal of the Korean Society of Living Environmental System, 12(2), 2005.06, pp.140-147. -

홍태훈, 정광복, 지창윤, 전과정평가(LCA)를 이용한 친환경 인증 건축물과 일반 건축물의 환경영향 비교 사례 연구, 한국건설관리학회논문집 , 제15권 제3호, 2014.05, pp.58-65.

T. Hong, K. Jeong, C. Ji, Comparison of environmental impacts of green and traditional buildings using life cycle assessment, Korean Journal of Construction Engineering and Management, 15(3), 2014.05, pp.58-65. [ https://doi.org/10.6106/KJCEM.2014.15.3.058 ]

-

고명진 외 3인, 주상복합 건물의 투입자재에 대한 LCI DB 구축, 한국생활환경학회지, 제22권 제6호, 2015.12, pp.884-890.

M.J. Ko et al., A study on LCI DB construction for input materials of residential-commercial building, Journal of the Korean Society of Living Environmental System, 22(6), 2015.12, pp.884-890. [ https://doi.org/10.21086/ksles.2015.12.22.6.884 ]

-

최두성, 전흥찬, 조균형, 산업연관분석법을 이용한 학교 건물에서의 환경영향평가, KIEAE Journal, 제16권 제3호, 2016.06, pp.57-62.

D.S. Choi, H.C. Jeon, K.H. Cho, Environmental impact assessment at a school building using input-output table - Focused on elementary school in Gyeonggi-do -, KIEAE Journal, 16(3), 2016.06, pp.57-62. [ https://doi.org/10.12813/kieae.2016.16.3.057 ]

-

R. Crawford, Life cycle assessment in the built environment, UK: Taylor & Francis, 2011.

[https://doi.org/10.4324/9780203868171]

-

H. Lim, S. Tae, S. Roh, Analysis of the primary building materials in support of G-SEED life cycle assessment in South Korea, Sustainability, 10(8), 2018.08, 2820.

[https://doi.org/10.3390/su10082820]

-

하수연, 계측데이터 기반 표본 업무시설에서의 용도별 에너지사용량 원단위 통계값 도출 및 분석, 이화여자대학교 석사학위 논문, 2020.

S.Y. Ha, Statistical analysis of energy use intensity by end use in sample office buildings based on measurement data, Ewha Womans University, Mater Thesis, 2020. -

원윤희, Prototype 사무소건물의 전과정 에너지 소비량과 CO2 발생량 원단위에 관한 연구, 광운대학교 석사학위논문, 2014.02.

Y.H. Weon, A study of life-cycle energy consumption and basic unit of CO2 emission of prototype office buildings, Master’s Thesis of Kwangwoon University, 2014.02. -

조수현, 서성모, 저탄소 건축물의 전과정 탄소배출 특성에 관한 연구, 대한건축학회 2016년도 추계학술발표대회논문집, 2016.10, pp.1367-1368.

C.H. Cho, S.M. Seo, A study on characteristic of life cycle carbon emission of low-carbon building, Autumn Annual Conference of AIK, 2016.10, pp.1367-1368. -

T.H. Kim, C.U. Chae, G.H. Kim, H.J. Jang, Analysis of CO2 emission characteristics of concrete used at construction sites, Sustainability, 8(4), 2016.04, 348.

[https://doi.org/10.3390/su8040348]

-

B. Berggren, M.. Hall, M. Wall, LCE analysis of buildings - Taking the step towards Net Zero Energy buildings, Energy and Buildings, 62, 2013.07, pp.381-391.

[https://doi.org/10.1016/j.enbuild.2013.02.063]

-

M.A. Cusenza, F. Guarino, S. Longo, M. Cellura, An integrated energy simulation and life cycle assessment to measure the operational and embodied energy of a Mediterranean Net Zero Energy building, Energy and Buildings, 254, 2022.01, 111558.

[https://doi.org/10.1016/j.enbuild.2021.111558]

-

P. Muñoz, P. Morales, V. Letelier, L. Muñoz, D. Mora, Implications of life cycle energy assessment of a new school building, regarding the nearly Zero Energy buildings targets in EU: A case of study, Sustainable Cities and Society, 32, 2017.07, pp.142-152.

[https://doi.org/10.1016/j.scs.2017.03.016]